The NSW Farmers wool committee will lead an industry-wide approach to reverse a shearer shortage…

A woolly solution to plastic pollution

In an era marked by increasing environmental concerns and a growing commitment to sustainability, the quest for eco-friendly alternatives to plastic has become crucial. Wool, a natural fibre with a rich history in Australia, is emerging as a promising candidate to replace traditional plastic materials such as polystyrene and polyester.

The environmental impact of plastic

Plastic pollution has reached alarming levels globally, contributing to environmental degradation, marine pollution, and the release of harmful chemicals.

Polystyrene, a ubiquitous plastic material that has been mass manufactured since the 1960s, insulates heat, absorbs shock and isn�t water soluble, which makes it useful for transporting goods like food and pharmaceuticals. However, it poses significant challenges due to its non-biodegradable nature and persistence in the environment. In NSW alone, around 12,000 tonnes of polystyrene is sent to landfill every year.

This is something that troubled entrepreneur Joanne Howarth, who has worked in the food packaging industry for decades. Joanne says she was devastated by the amount of plastic waste the industry generated.

�I�ve always been passionate about the planet,� she says, �and it was obvious that there was a need for a sustainable alternative to polystyrene.�

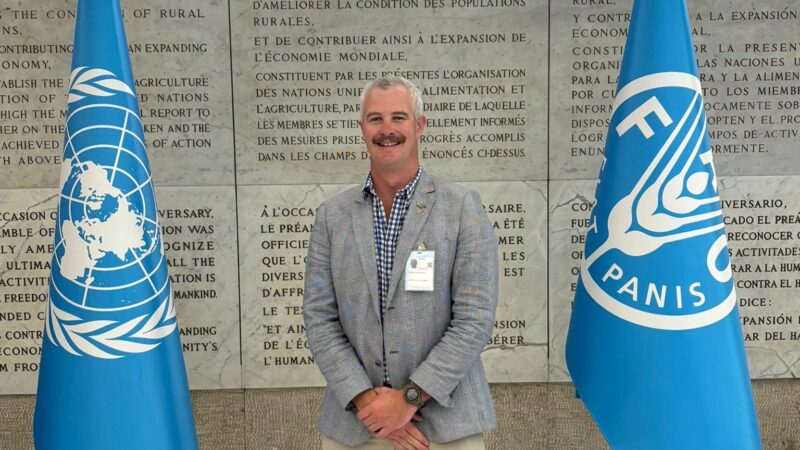

After several years of research and development, Joanne founded Planet Protector Packaging: a sustainable packaging start-up where wool is the hero.

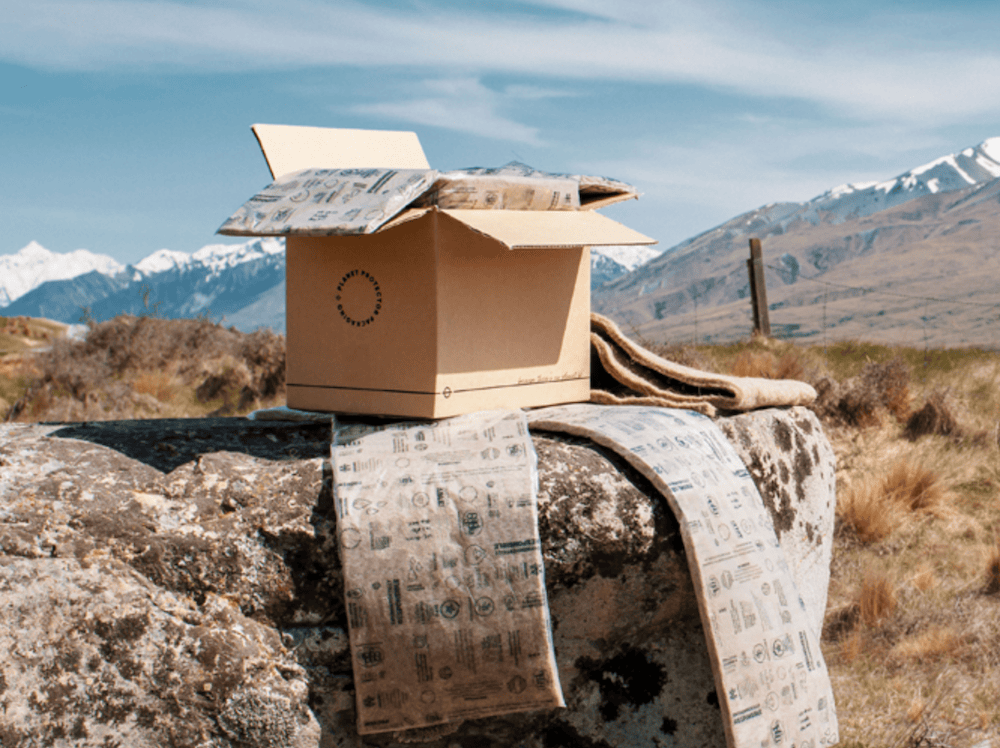

When Joanne began researching polystyrene alternatives, she found that wool had many unique properties, such as its natural insulating capacity and cushioning ability, making it an attractive option for packaging materials. Wool is derived from the fleece of sheep, which can be shorn annually without harm to the animal. Thermally, it outperforms polystyrene.

In contrast, plastic production relies heavily on fossil fuels, contributing to resource depletion and environmental pollution.

It took Joanne and two textile physicists a year to find the right kind of wool that was needed � coarse fibre, rather than fine merino � and a further three years to develop Woolpack: the wool packaging that is now the cornerstone of her business.

�It�s deceptive. People might think, �Oh, it�s just wool in a sleeve� but it�s much more than that. And it�s made from a waste stream diverted from landfill.�

Joanne Howarth, founder of Planet Protector Packaging

Planet Protector Packaging has since replaced 7.2 million polystyrene boxes with Woolpack, diverted 3,500 tonnes of wool from landfill and increased income for farmers and processors.

The polyester predicament

Wool�s potential as a sustainable alternative extends beyond packaging.

Wool possesses natural fire-retardant properties, making it a safer choice in construction materials compared to synthetic alternatives. It has even been used to clean up chemical spills, or as mulch or seed beds.

Additionally, wool garments offer breathability, moisture-wicking properties and insulation, making them a sustainable choice in the fashion industry.

When it comes to the main alternative to wool fabric, synthetic fabrics such as polyester or acrylic are usually the answer. These fabrics are versatile, durable and cheap, and are made of plastics derived from crude oil.

However, through wash and wear they release thousands of tiny plastic fibres which are found everywhere in the environment. It is estimated that 0.6-1.7 million tons of microfibres are released into the ocean every year, and around 35 per cent of microplastics in the ocean come from synthetic clothing.

Wool, on the other hand, is biodegradable in both land and marine environments, meaning it has a long life as a garment yet breaks down relatively quickly in landfill.

But is wool really that sustainable?

Wool remains a frontrunner in sustainable textiles. Woolgrowers in Australia are pioneering eco-friendly farming methods, emphasising the recyclable nature of wool and sheep’s adaptability to challenging landscapes.

Unlike synthetic fabrics, wool doesn’t release microplastics, and its role in the circular economy is gaining traction, with companies recognising its potential for creating long-lasting, high-quality products while prioritising land and biodiversity health. Moreover, the wool industry is actively addressing greenhouse gas emissions, implementing techniques on individual farms to offset carbon footprints such as changing the types of pasture plants, improving soil management to increase carbon storage, and planting trees.

Collaborative efforts, such as Greening Australia’s partnership with wool growers in Tasmania, has also had tangible results, restoring 1,000 hectares of landscape by planting 250,000 native plants, and contributing to one of Australia’s largest revegetation projects.

Riding on the sheep�s back

Australia is a country with a long history of sheep farming, and is often referred to as �riding on the sheep�s back.� Today, woolgrowers are proud that Australia has the world�s most advanced wool industry, with innovative and sustainable farming practices being implemented to secure the industry�s future.

New uses for wool as part of sustainable alternatives to plastic can also offer more opportunities for local producers.

Educating consumers and industries about the environmental benefits of wool will also be crucial in fostering a shift towards more eco-friendly choices.

By reevaluating perceptions, raising awareness and fostering a commitment to sustainable practices, wool can take centre stage as a valuable and sustainable alternative to plastic waste.

If you enjoyed this story, you may like to read about the hungry caterpillars that can eat through plastic waste.