Agtech in Australia is big and getting bigger; it seems every week there is a…

Farming data: new tech delivers results

It was tackling the adulteration chewing up to 50 per cent of his market that first led Phil Prather to blockchain technology.�

�The tea tree industry is coming under pressure from competition from China, which typically offers adulterated and very impure oils,� says Phil, CEO of Downunder Enterprises and chairman of the Australian Tea Tree Oil Industry Association (ATTIA). �

Thanks to well-established testing, auditing and accreditation systems for tea tree producers and distilleries, the governance � and importantly, data to support it � were there. So a pilot commenced with agtech startup, Geora, to build a digital traceability and certification management tool. Blockchain, a secure and decentralised kind of digital ledger that records and verifies transactions across multiple computers, was once better known for its use in the world of cryptocurrency, but is now applied to a wide range of uses. In this case, it was chosen for its distributed database structure and consensus-based smart ledger approach, which sees transactions coded into immutable �blocks�.�

�We have a gatekeeper process, a check system of what quantities of oil can be placed on the blockchain, through to that distillery system verified via Code of Practice audits,� Phil says.

�We were confident as an industry we could implement blockchain once we got the right solution or right tools.�

Yet even as commercialisation progresses, the impetus for blockchain is shifting to validating sustainability credentials through the supply chain.�

�Use of blockchain is going to become a pull, as opposed to a push. It�s the mandate of all companies on their sustainability footprint that�s really going to drive this,� he says. �We�re exploring what types of inputs we�re going to need at an industry level to deliver traceability right through to the manufacturers, so they can meet their legislative requirements and reporting imperatives.� �

Proving green compliance for lending purposes using blockchain went into pilot this year. Queensland-based Leather Cattle Company is adopting blockchain to meet reporting covenants of its NAB Agri Green loan. The aim is a standardised record of environmental impact and steps to reduce emissions, creating a trustworthy record the organic farm can share with interested stakeholders in the beef supply chain. To help, it�s planting 1,200 hectares of the Leucaena legume, shown to reduce emissions intensity of livestock by 20 to 40 per cent across grazing spaces.

�Working with NAB and Geora to track this digitally means we can actually prove the impact of these green projects,� Leather Cattle Company owner, Melinee Leather says.

Like Melinee, Phil wants blockchain to substantiate what the tea tree industry is doing so it can compare with other industries plus competitors globally.

�If you have the data and technology, then you�re going to have the operating model. But it has to be operated at both the farmer and manufacturer level,� Phil says. �We�ll then get the benefits on adulteration in the slipstream.��

Making data actionable

Blockchain is one fast-evolving technology with mounting impact on farming. In the field, on water tanks or up in the air are an array of other data collecting technologies like smart sensors, electronic identification tags (eIDs), smart animal collars, drones, satellite mapping, smart spraying cameras and connected farming equipment.�

But while innovation is still occurring in the hardware, it�s software platforms, mobile-based apps, network connectivity, data analysis and modelling, machine learning, as well as sharing and aggregation tools finally making data actionable for farming use cases. These fit into a few buckets, albeit with nuances depending on geography and farming type: productivity; supply chain transparency and product traceability; sustainability/ESG; natural capital reporting; carbon sequestration; and operational management.�

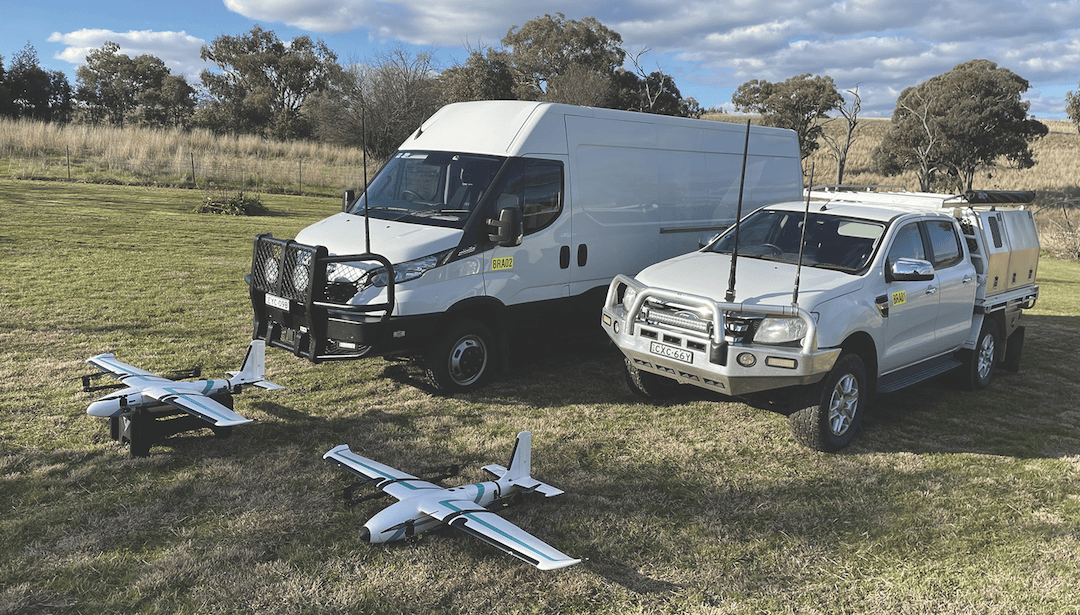

Where Bralca owner and director, Ben Watts, has seen the big shift in the last 12 months is the processing, analysis and machine learning components of harnessing data for timely decision making. Western NSW-based Bralca is a grower and service provider around drone technology.�

�Drones are collecting data processed in a six to 12-hour turnaround, giving us individual plant detail in a cereal, winter or cotton crop. We can run that through analytics on our cloud servers and quickly get a picture of which plants within that paddock are performing and which aren�t,� Ben says.

Farmers still need ground truth to ascertain whether an issue is moisture versus pests � for now, anyway. �But it means we can, on any given day�and at the farmer�s choice, collect data and make an informed decision,� says Ben. �We can take that plan to inspect a paddock, run it through software and turn that into a treatment plan we can load back into an existing machine. That�s where I see technology empowering us as farmers. Data that only gives you more information just gives you a headache.��

Having data at Broden Holland�s fingertips was the catalyst for an explosion of productivity gains at his family�s Koolpari Enterprises in Young. Yield monitoring in the hopes of spreading variable rates across its mixed crop farm had been underway, but complexity inhibited progress.

�The thing is how much time and effort you want to spend on trying to map maps and layers,� Broden explains. �I believe everyone has a huge amount of data they could be using. The reason it�s not getting implemented is because the software is too hard and difficult � and not convenient. I want to drive through the paddock and if I�ve forgotten to make that protein map, quickly do it on my phone.�

Broden began working with Australian-owned CropScanAG on nutrient management app, N-Gauge. �It enables me to make a contoured map with that protein layer. I convert that into a urea map, add strips, plus rates, within a couple of minutes. I can push a button, send it to my John Deere app and it�s in the tractor.��

Tackling nitrogen has seen Koolpari go from six per cent variation rates to one per cent, generating approximately $1.2 million from better yield over the last three years. �Without that data� our average protein would have been the same, but average yield would have been a tonne less,� Broden says. �

Addressing nitrogen is being followed by incrementally solid gains from tackling sulfur and magnesium levels. It�s also necessary in fungicide trials.

�In the last three years, we�ve done the same trials we did 20 years ago but have clear-cut decisions now. We know when we spray a fungicide, we�re going to get a good hectare and good year because of what we�ve done with nitrogen. We didn�t see that before because we couldn�t measure it,� Broden says. �You can have all the data in the world. But if it�s not in the palm of your hand when you�re looking at that crop, you go back to your computer and second-guess yourself.��

Getting your data ducks in order

Most importantly, Broden has learnt the valuable lesson first-mover industry sectors had drilled into them through data and technology investment trial and error: Know your �why� first.

�The mentality of a lot of people is to grab all this data together, look at a map for 10 hours and still not know what to do. I�m saying let�s look at our issue, the best layer to fix the issue and use it,� says Broden.

Koolpari�s yields are climbing higher as a result and it averaged a nine-tonne red wheat crop last year. �I�d love to grow a 10-tonne crop. Now I think it�s doable,� he says. �Never would I have thought in my wildest dreams we could grow that much wheat here.�

Bralca is running workshops with NSW Farmers to help growers share thinking and up their data game. �We can have two successful farmers side by side using very different approaches. If they choose the profit drivers for their business they identify with, that�s�obviously what�s keeping them awake at night or what they�re passionate about,� Ben says.�

�This is preferable to spending $20,000 on tech and waiting for it to change my business. It doesn�t work that way. Work the other way back: What is the pain point? What information do I need to help make that decision? What data processing will I need to turn that into something useful?�

Similar pragmatism lies behind the Landcare Farming Program Benchmarking Soils Project, developed to help landholders establish benchmarks for soil carbon levels and greenhouse gas emissions. Nine participants explored ways to improve carbon sequestration through groundcover and pasture management, while increasing productivity. The project involved FarmLab, CSIRO, Soil Future Consulting and Optisoil. Growers were given an Environmental Farm Assessment tool and trained in remote sensing imagery.�

Participants John and Samantha Stokes, who run the Dorper prime land enterprise north of Tamworth, see better soil fertility and pasture production generating external income streams through ecological monitoring and soil biology consulting. There�s also the chance to add value to red meat products through sustainability accreditation and labelling. Tim and Courtney Skerrett at Mulla Creek, meanwhile, seek to produce sustainable quality beef while increasing soil health and biodiversity. They�re looking to earn income from Australian carbon credits by building carbon stores and biodiversity through a regenerative agriculture approach.�

Maturing data approaches

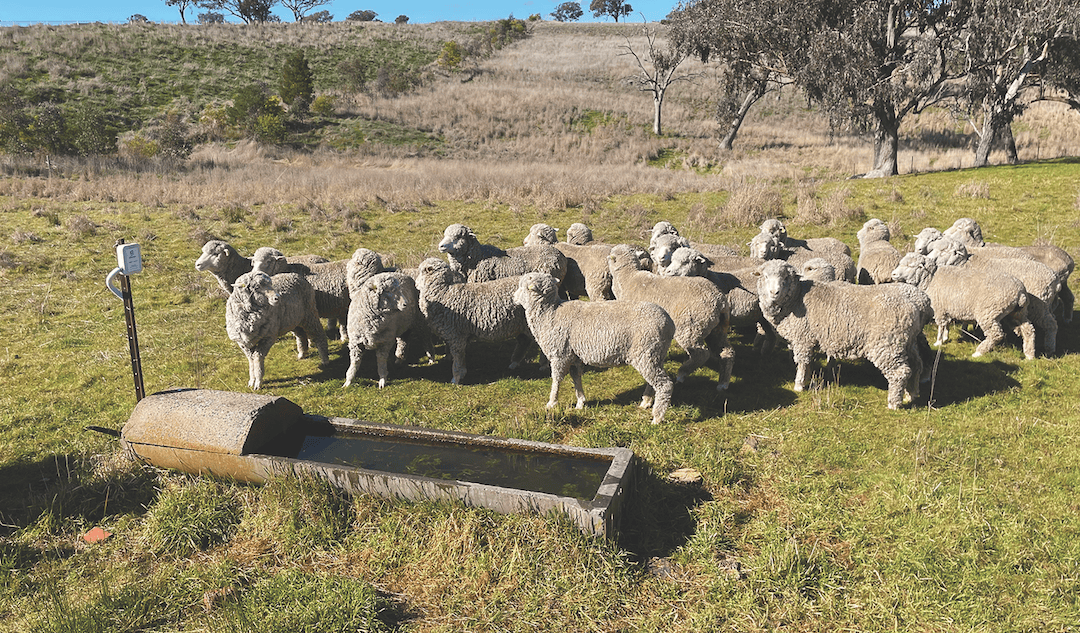

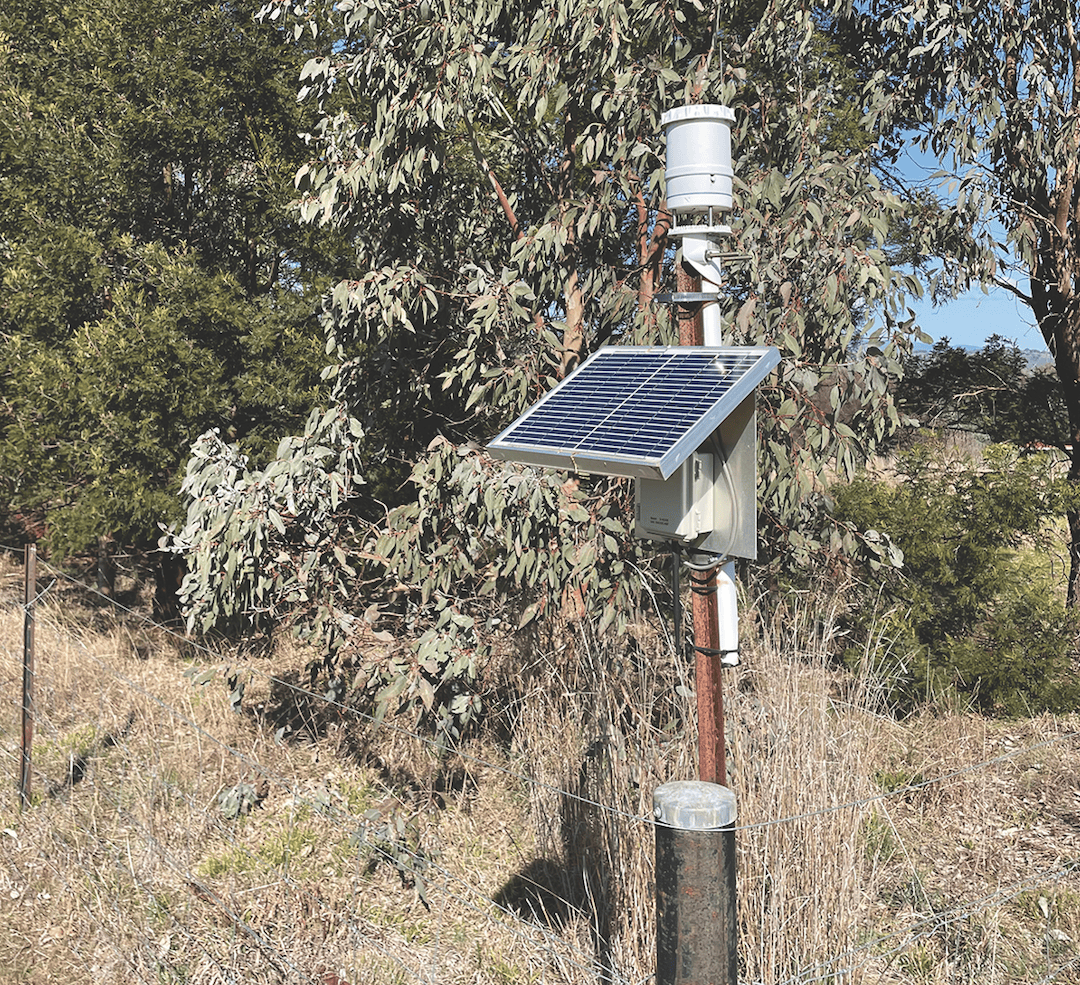

At WA-based Coolindown Farms, Belinda Lay is increasingly tapping data from Internet of Things (IoT) sensors, eIDs, sheep location devices and temperature collars for risk mitigation and performance enhancement. Paving the way was a co-funded research project with Meat and Livestock Australia using devices and data to generate ROI in a mixed farming enterprise.�

Belinda now runs her own data store to collate historical and current data sets to uncover new data insights and test management theories. Power BI helps visualise data, while a data scientist builds models against different parameters she can manipulate.

�We compared animal movements with rainfall crop yield and soil moisture to gain insights into different areas. The correlation is only possible if your data is interoperable,� she comments.�

But it had to start somewhere and for Bralca and Coolindown Farms the obvious place was water. Coolindown fitted Waterwatch level sensors to tanks, connected to an app and AxisStream data platform. This resulted in a 70 per cent reduction in inputs and ROI in a year.

For Belinda, data success is about consistency and context. �If one year you do fleece weight with bellies in and the next year you take the bellies out, you can�t compare your wool production year-on-year because 500g to 1kg of belly is out of your fleece weights. That�s consistency.�

Context requires farmers to start with the end in mind. �For me, it�s a 60kg sheep that�s cutting at least 4.5kg of wool, preferably giving birth to twins and doesn�t need mulesing,� she says. �If that�s what I�m wanting, I�m going to start recording pregnancy scanning data, recording fleece weights, and bodyweight.��

What’s next?

Biosecurity is the next outcome Bralca is looking for, and Ben is harnessing electronic national vendor declaration (ENVD) using blockchain and the Bioplus application for compliance, easier administration and access to premium markets.

�Consumers and customers increasingly want to know if there�s validity to the information the farmer signed off. That information we need to collect is the same information that helps us know whether we�re making the right decisions throughout the season,� Ben says.

Camera spraying and drone technology are additionally giving farmers better tools to manage pests, from weeds to wild pigs. An advancement many look forward to is enhanced satellite imagery to ascertain soil moisture and carbon analysis virtually.

At an industry level, multiple projects led by government, universities and R&D organisations are striving for ways to aggregate and benchmark data sets to better understand production, seasonal or regional trends, and support imperatives for carbon/ESG reporting and revenue streams. Just take the�Federal Government�s Integrated Farm Management program, encompassing carbon and biodiversity through a circular agriculture approach. Or there�s the �Know & Show Your Carbon Footprint� initiative to develop a cross-commodity platform for growers to better understand baseline carbon emissions and residual footprint across their entire enterprise from Agricultural Innovation Australia (AIA). All point to the growing value of data management, ownership and shareability for farmers.�

�The evidence has to be very sound, because we�re basically creating financial products on our farms with the development of soil carbon capture and biodiversity coming along,� adds Phil.

To read more about modern agricultural practices, click here.