The salad was once a domain owned by the iceberg, but these days an array…

Innovations in the NSW cotton industry

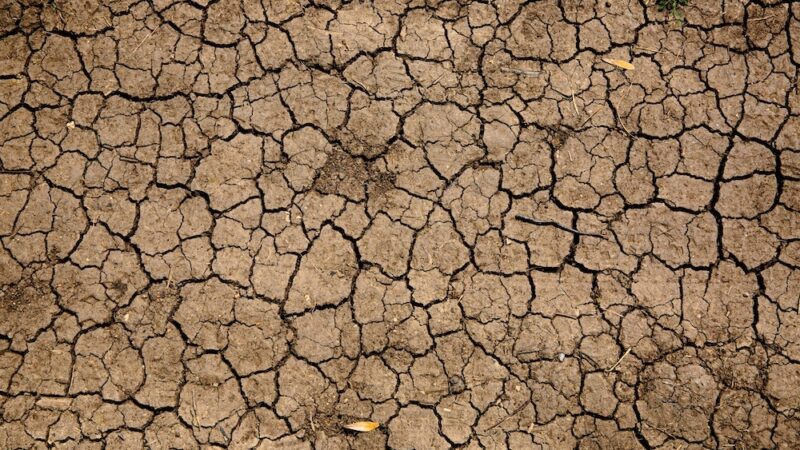

Dry land, irrigation, integrated pest management, crop rotation. Most of these words and terms are not part of the common parlance when people talk about the cotton industry. But innovations in the cotton industry are on the rise.

Often cotton is a crop farmers decide to plant if the soil moisture profile enables it, and if rainfall allows it. It is a break crop and one to create fertility. And this is against a national reputation for producing the best cotton in the world.

Australian-grown ginned cotton is predominantly exported to be made into clothing and other apparel, but that market competes against a growing demand for cottonseed oil from the hospitality sector � locally and overseas � and cotton meal from Australia�s feedlot industry.

Improving water use efficiency

Executive Director of the International Cotton Advisory Committee Kai Hughes recently said Australia is one of the few countries in the world at the cutting edge of cotton research. NSW Department of Primary Industries (NSWDPI) has led a benchmarking research project since 2006, analysing water use efficiency against production. It builds on benchmarking research from 1992 to 2006.

Research from NSWDPI and Cotton Research and Development Corporation (CRDC) revealed water usage had fallen from 1.43 Ml/bale in 1995, to 0.74 Ml/bale in 2020. Cotton growers have decided their next challenge is to benchmark against a 2024 target of 0.71 Ml a bale.

Production efficiencies are driven primarily through improvements in irrigation infrastructure and management efficiencies, underpinned by research and development. From the industry�s perspective, change includes informing public debate about cotton growing and water use.

CRDC Executive Director Dr Ian Taylor says Australian cotton growers are committed to continuously improve their water use efficiency. When calculating water use and implementation over time, researchers took into account all the water used on the farm to produce the crop.

�This includes all water coming onto the farm from rivers and bores, all rain falling directly on the crop, harvested rainfall runoff, all soil moisture used

by the crop, and water lost through evaporation and seepage during storage in dams and delivery to the paddock,� Ian says.

Levels of water withdrawals for irrigation in Australia are regulated by governments to deliver sustainable water use from healthy river systems. There are clear limits on the volume of water that can be used, and this changes each year based on seasonal conditions. Within this regulatory framework that limits water use, Australian farmers work to increase the efficiency of water allocated to them, and part of that is choosing which crop to grow each year with the available water.

Cotton as a pillar crop

At Boggabri, Andrew and Heike Watson grow cotton as part of a summer crop rotation, but they use Namoi River seasonal irrigation licences, groundwater, supplementary high flow allocations and re-use dams to drive their decision.

�Cotton is our pillar crop,� Andrew says. �It comes into rotation every four or five years, depending on water availability, and it helps in weed and nutrition management. Its water use is equivalent to corn or fully irrigated sorghum.�

Andrew says he allocates 7.1 Ml/ha to grow cotton or corn, compared to 3.1 Ml/ha for wheat.

�We only grow canola or sorghum when we have supplementary irrigation available,� he explains.

Cotton from wheat stubble

Charles and Celia Boileau, who grow cotton crops on dryland country near Delungra, utilise the water-saving efficiency of last season�s wheat stubble to plant cotton. But their decision to grow cotton is still dependent on sufficient rainfall and the soil moisture profile. They grow cotton in rotation with wheat, sorghum or chickpeas.

�Our decision to plant is based on price forecasts, commodity drivers and the weather conditions. In particular what subsoil moisture we have in the country after the wheat is harvested,� Charles says. �I focus on maintaining good ground cover on the country, so the cotton seed is protected after planting.�

He farms in a high rainfall zone, with an annual average of 71cm, on land that is sloping with roll-over contours. Paddocks are deep self-mulching black soils with a reasonably high clay content.

Charles expects to plant cotton this year, given the soil moisture profile is full after winter.

The couple also grow cotton as a partner in seed trials, to measure emergent, growth and yield of these seeds against quality and growth per area, and environmental impact.

�Last year we grew a CSV seed trial and have another one this year. It gives you more flexibility in weed control. The varieties we sow have Roundup Ready herbicide in them,� Charles says. �We usually put some pre-emergent on the country straight after we sow; then spraying occurs based on rainfall and what weeds emerge and survive the pre-emergent herbicide. This year we only applied weed control twice, and used only one insecticide spray, to take out the mirids but not the beneficial and predator insects.�

He also utilises the cold conditions of winter-time to avoid bacterial growth problems in the crop.

New innovations in cotton

Other innovations led by researchers in collaboration with CRDC and NSWDPI have been the use of integrated pest management and other ways to reduce the use of chemical pest control methods. This research has led to the development of DAT11 (Metarhizium sp.), an entomopathogenic fungal isolate demonstrating effective control of insect pests in cotton � including Helicoverpa spp., and sucking insects like green mirids, silverleaf whitefly, green vegetable bugs, Rutherglen bugs, fruit fly and mealy bugs.

More recently, botanical products have also been identified as effective in controlling Helicoverpa spp., green mirids, green vegetable bugs and silverleaf whitefly.

Research is focussed on increasing the use of biologicals and biopesticides to help drive production efficiencies, and reduce growers� reliance on synthetic crop protection chemicals � annual insecticide use in Australia is currently valued at more than $8 billion.

Andrew Watson has been using integrated pest management (IPM) to encourage beneficial insects and biological control across all of his crops. He has been planting vegetation belts since the 1990s to build habitat for beneficial insects.

�The cotton industry has historically had a reputation for high insecticide use. IPM is a game changer for us,� Andrew says. �As each year went by, we measured the insect population and as we saw the pest insect population rise up, the predators and beneficial insect population also rose.�

In the past couple of years he has turned to technology to support the beneficial insect population, using drones to seed predators into his cotton and corn crops. Drone seeding Eretmocus hayati wasps into his crops has been successful in controlling silver leaf fly and green mirids.

While he still uses a granular insecticide at sowing to protect the newly emerging plant shoots from insects, he said releasing beneficial insects into the cotton and corn crop had been effective in reducing insecticide use.

�It�s been quite effective in reducing our insecticide use to almost nothing,� Andrew says.

�Before we began using drones, our yield averaged 11.5-12 bales per hectare (prior to the drought). Last year we averaged just under 14 bales per hectare.

�Whole farm water efficiency, minimising nutrient flows and IPM underpin our environmental management systems, and are making Australian cotton a world standard, which drives premium pricing,� Andrew says.

If you enjoyed this story on innovations in the cotton industry, you might like our feature on advancements in the lettuce industry.