The National Farmers Federation 2030 Roadmap outlines the government�s plan and vision to �exceed $100…

Regenerative ag: the tides are turning

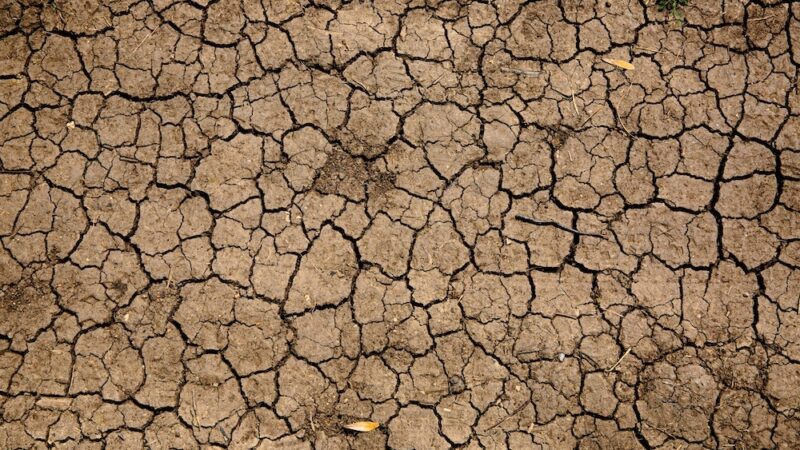

There is no doubt that change is upon us. Global temperatures are rising, extreme weather events are more frequent and more extreme, land usage in some areas is changing dramatically as weather patterns make the land less viable. The mantra often quoted by many farmers these days is that they aim to leave their land better than when they found it for the next generation, and that means a focus on regenerative agriculture, in order to have a healthy handover.

Happily, there is a ground swell of regenerative farming activity, not only in NSW but around Australia and across the world, as increasing numbers of young farmers and rural business people look for new ways to manage the land. In the USA a recent survey showed that on any given day there is 227,965 acres of farming land undergoing regeneration.

Schools of thought

Over the past few years there has been a huge increase in the number of enrolments in agroecology, regenerative farming, organic farming and agricultural science courses at universities, TAFEs and colleges.

The National Environment Centre � a TAFE college in Albury � is a case in point. The centre runs one of Australia�s leading agroecology courses � a Diploma in Organic Farming, turning out many graduates who have gone on to be practical examples of the new way of managing the soil, plants, animals and the general environment.

Gerard Lawry is the head teacher for the course, and he is also a 15-year veteran of teaching agriculture, permaculture, organics and practically allied courses. He has also been a mentor to hundreds of farmers looking to apply sustainable practices on their land.

Gerard says there has been a consistent rise in the number of people wanting to delve deeper into soil chemistry, plant biology and the full raft of agroecological teachings.

�There is a massive change going on and it�s multi-generational,� he says. �The ideas around agroecology are getting a much better reception these days than they did in the past.�

While he points out that there are now many courses being offered in regenerative agriculture, many simply focus on soils, which is only one aspect of the process. He says that to be truly regenerative farmers need to look at the total environment and that includes such things as water management, revegetation, better soil testing, a greater understanding of plant biology, building habitats for native birds and animals and so on.

�We need to be thinking of the whole package, that is using ecological services to manage the entire agricultural production system,� Gerard says.

He delivers a strong message about the application of the total package to his students as he believes that unless we take into account the whole ecosystem, the ideal of regenerating land could fail. �To drag the luddites into the light, you have to be extreme,� he quips.

Dr Hanabeth Luke is the Senior Lecturer in Science and the course co-ordinator for regenerative agriculture at the Southern Cross University.

She says there have been 500 enrolments across the University�s regenerative agriculture oriented courses which include a number of Diploma, Graduate Diploma and Degree qualifications.

Dr Luke says the students are varied in age from school leavers to some in their sixties. The popularity of regenerative agriculture courses has prompted the University to look at obtaining farming land for a practical application of the courses. In addition, she says the university is now looking at the potential of a Masters Degree in Regenerative Agriculture.

On the ground

John McKay is owner and Director of ECTOL � a family owned business created by farmers for farmers, and the provider of unique solutions for the changing climate and economic dynamic. Ectol specialises in plant and crop nutrition, developing products and protocols specific to each farmers� crop and soil operation.

John says there is a lot of confusion around the definition of regenerative, and around the word sustainable. �In my mind they both mean the same thing,� he says. �Because in modern farming practices we are seeing a loss of production and of vital top soil. The rising costs of inputs such as fertilisers means farmers have to look elsewhere.�

ECTOL�s products include a core nutrient range, a certified organic range and extended nutrient range providing soil nutrition in 1000 litre, 200 litre and 20 litre volumes.

�We have always been in this spectrum of sustainability and regeneration, but my understanding is that the science behind it is to build up soil carbon. We have seen with the overuse of some chemicals and the resulting loss of soil carbon affecting productivity.

John says that in the past some farmers found inorganic elements stimulated production and provided higher yields, but he adds: �We have found that yields are declining because the elements are being bound up and can�t be used by the plant. We aren�t getting the response from a bag of super that we used to get.�

ECTOL was born with a long-term vision to improve farm production using smart science, in harmony with nature, says John.

Not just dirty water

It�s not just deep science that is helping in the regenerative process. Jason Nicholls is an entrepreneur who has built a large business from very small beginnings to service the growing needs of farmers looking for sustainable, environmentally friendly fertiliser.

He has turned �worm wee� (also known as worm juice) into a godsend for farmers unable to pay the escalating prices for fertiliser. �For us, the rising cost of fuel and fertiliser has been a blessing,� he says.

While worm juice was always known for its soil health benefits, there were detractors for its use. But Jason says the benefits are undeniable. From a credibility perspective Jason had his juice biologically tested. �It is full of microbes, and applying this into your garden or soil will unlock precious nutrients which are valuable for healthier, stronger plants and crops,� he says.

Jason began selling his worm juice by the bottle on an almost door-to-door basis, He says his wife accused him of selling people �dirty water�, but he was convinced in the benefits and the future of the product. His company Worm Solutions, which is based in Albury, is now producing tens of thousands of litres of worm juice a year.

Worm Solutions claims the added nutrient in worm juice helps build a soil profile capable of sustaining itself into the future without the requirement of adding synthetic compounds.

With the help of local farmers, Jason has been able to show the benefits of the worm juice delivering increased production and more sustainable land practices as an alternative to costly fertilisers. He is also encouraging others to compost base and worm juice production and he is producing worm farms for those who want to do it themselves.

��I am now manufacturing worm farms from Mackay in Queensland to Tassie, and 200 were made this year,� he said with �We have now sold worm farms from Mackay in Queensland to Tassie and 200 were made this year,� he said.

Actioning land management

The Green Collar Group is Australia�s largest environmental markets investor and project developer.�

It defines its services in four major areas � Carbon, Water, Nature and Plastic � and in each of these areas the company says it works in partnership with farmers, graziers, traditional owners and other land managers to identify, implement and monitor the projects that deliver economic, environmental and social benefits.

According to Susan Horn, the company�s head of marketing, Green Collar has been working with farmers and others on land regeneration since 2008.

She says that the regeneration process is not just about storing carbon, it also involves high level management of water resources, ground cover and biodiversity to mention a few.

The company delivers diverse projects to assist in the maintenance of a healthy environment. In Queensland, Green Collar is working with farmers to improve water quality run off that can impact the great barrier reef.

Using a mechanism called Reef Credits � a voluntary environmental market that addresses the issue of poor water quality at the Reef � managers are paid for improved water quality resulting from their on-farm actions, without compromising the productivity of their land.

The projects focus on reducing the flow of nutrients (namely Dissolved Inorganic Nitrogen) to the Great Barrier Reef through improved cropping practices, or by establishing wetlands. Repairing gullies also generates Reef Credits by preventing fine sediment erosion. Each Reef Credit is a tradeable unit representing a quantifiable amount of nutrient or sediment prevented from entering the Great Barrier Reef.

Reef Credits are sold to businesses, investors, philanthropists and governments seeking to reach water quality targets or achieve corporate ESG or compliance outcomes. The revenue generated from Reef Credits provides land managers with an additional and diversified income stream, that supports ongoing improved practices.

Eco-Markets Australia is the independent administrator of the Reef Credit Scheme.

The company is also involved in carbon farming which means that participating farmers are paid for undertaking environmentally positive land management actions such as looking after the environment by reducing greenhouse gas emissions or by storing carbon in vegetation and soil.

According to Green Collar, carbon farming does not mean locking up the land. They contend that farming and good environmental land management can work together.

Soil enhancement

A new method of applying compost � in the form of compost pellets � is opening up affordable ways for graziers to use commercial compost.

High quality compost is set to become a major player in agriculture, after the NSW Environmental Protection Authority (EPA) invested close to $100m since 2013 via its Waste Less Recycle More program to develop high-quality commercial compost industry.�

For graziers, commercial compost can be a wise long-term investment in the health and productivity of the land. It is rich in nutrients and can improve soils and boost crop yield.

Commercial compost has traditionally been applied by spreading it over the surface of the soil.

But to do this, graziers need large volumes and, even then, spreading compost across the surface doesn�t guarantee that it gets into the soil.

And that�s why applying compost in the form of compost pellets could be a game changer.

To test the potential of compost pellets the EPA funded compost pellet trails by MRA Consulting group through an Organics Market Development Grant.

One trial site is Steve Leisk�s farm near Molong in the Central West where the compost use has been an element in transforming the property from sandy paddocks into rich fertile soil.

As part of this trial, loose commercial compost was put through a pelletiser machine to make pellets.

The compost pellets were then put in the tube of an airseeder and planted with the seed, putting the compost exactly where it was needed � making it more cost-effective and easier to apply.

�The end result is a truly remarkable paddock, and its production is phenomenal,� says Steve. �We�re basically running at four and a half times our previous production levels.�

In promising news for the grazing industry, the trial more than tripled triticale yield, increasing revenue by $1,000 per hectare.

Compost expert Virginia Brunton from MRA Consulting Group says compost is a vital ingredient in farm productivity.

�I realised, principally talking to farmers, that a lot of their production problems were due to lack of carbon in the soil � a lack of organic matter.

�And one of the main sources of organic matter can be compost. Carbon in soil drives the chemistry and biology and everything that makes a farm productive.�

Phosphate solution as fertiliser prices continue to climb

With growing concern among farmers about soaring fertiliser prices brought on by supply chain disruptions, contemporary resource company Agriflex Pty Ltd is inviting farmers to consider finely crushed phosphate rock for direct application on crops and pastures.

Agriflex Pty Ltd is wholly owned by Centrex Limited (ASX:CXM) and has recently begun mining at its Ardmore Phosphate Rock Project, just south of Mount Isa. The project has been several years in the making and is now operational at a very fortuitous time for farmers.

Agriflex agronomist Walter van Leeuwen, who joined Agriflex in February this year from S&W Seed Company � where he was Vice President of MENA Sales � said that many farmers are unfamiliar with Direct Application Phosphate Rock (DAPR).

�We crush phosphate rock to less than 4mm so that it becomes a slow-release organic fertiliser which consistently adds phosphate to the soil profile and is therefore a very cost-effective way to augment crop nutrition,� Walter said.

�We encourage farmers to talk to us about crushed phosphate rock and whether it is suitable for their needs.�

DAPR is also known to strengthen biotic microbial activity and release additional tied-up nutrients. It is better suited to high rainfall areas or irrigated crops with acidic soils (pH6-6.5) and can be applied in conjunction with Single Superphosphate and other fertilisers to provide combined immediate and long-term benefits.

Centrex Limited�s (ASX:CXM) much anticipated Ardmore Phosphate Rock Project in North West Queensland mined its first parcel of high grade phosphate rock last year with an initial 25,000 tonne parcel being made exclusively available to farmers for use as direct application phosphate rock.

The lion�s share of the mine�s future product is intended for the phosphatic fertiliser production market, and the company is already supplying finely crushed phosphate rock to an organic fertiliser producer on Australia�s east coast. But as contract negotiations with other producers intensify, it is eager to make local farmers aware that Australia�s reliance on imported phosphate could soon be over.

Centrex announced its plans to mine phosphate rock at Ardmore in 2018 to help reduce Australia�s increasingly risky reliance on imported phosphate. Over the past year, economic conditions and phosphate rock prices have improved substantially, paving the way for the commencement of mining operations at Ardmore � a key contributing factor being the benchmark 70 per cent BPL rock phosphate price which has climbed month on month over the past year, reaching USD$250 per tonne in May.

�Phosphorus is critical to the production of food crops and in pasture for livestock and yet we are almost entirely reliant on imported product,� Walter said.

�Direct application phosphate rock (DAPR) is an effective and affordable soil nutrition solution and Agriflex can deliver direct to any farm in Australia.�

Regenerative farmers can double income with carbon credits

One of the most important aspects of running a soil carbon project is adapting your management to build carbon rich, healthy soils with productive pastures. This is the core business of RCS and has been for more than 30 years.

RCS is Australia�s leading educator and advisor in regenerative agriculture and works with landholders to profitably build soil health and productivity in agricultural landscapes.

�We�ve had the opportunity to work alongside thousands of farmers as they transform their land and business, and we are now seeing how that can translate into soil carbon below ground,� said RCS chief of delivery David McLean.

Carbon aggregator CarbonLink recently released preliminary soil carbon findings linked to properties where landholders had graduated from RCS programs and adopted RCS principles.

CarbonLink commercial director, Andrew Gatenby said: �The results showed that producers on extensive grazing properties can double their income by undertaking a soil carbon project that generates carbon credits�.

�The top 20 per cent of beef producers in southeast Queensland implementing time-control grazing can generate $100/ha/year, and with a well-managed soil carbon project this can lift to $200/ha/year (net of costs-unaudited),� Andrew said.

�To build soil carbon your ecosystems need to be regenerating. That is, spiralling up towards greater diversity and health, rather than spiralling down towards degradation,� he said.

�Combine this with more hydration, resilience and access to new income streams � like natural capital and biodiversity payments � and the health of the land, livestock, business and people will benefit.�

The evolve bladerunner

What originated as a cover crop crimping machine is quickly evolving to cater to changing conditions and benefit farmers in the short and long term.

The Evolve Bladerunner’s first prototype was designed and built in November 2020 as a way to sustainably terminate thistles in pasture and crimp cover crops. �The results astounded us,� cattle producer Gus Hickman from Woodstock said.

�Not only did we eliminate a variety of weeds, but we were also able to influence the growth of desirable grasses and clover which shot up.

�Since then we have seen a dramatic change in weather patterns and an increase across the board in input prices. Evolve Engineering, as the name suggests, is evolving with these changes and paving the way for sustainable enterprises by allowing producers to reduce input costs and manage the challenges that come with increased rainfall.

�We are seeing a number of key influences in why farmers are contacting us interested in investing in our machines and leaning towards a more sustainable approach to improving their seasonal practices both in pasture and cropping,� owner Joe Fleming said.

Stock prices, the cost and availability of chemicals, fertilisers and inputs and increasing weed resistance are all weighing on producers and pushing them to seek alternatives. Evolve Engineering is providing this alternative and allowing producers to maximise production efficiency per acre by avoiding elimination of desirable pasture with broadleaf chemical sprays.

�I think farmers are realising now how the continual increase of inputs is really hurting their profit margin. It�s just not sustainable anymore. It is really exciting that we can provide a multi-purpose alternative to Australian farmers, helping them to overcome these challenges and make the most of the good seasons we are seeing.

�The applications of these machines are only limited by the producer’s desire to innovate and implement new practices. An example of this is Gus Hickman using the Bladerunner to knock down seeding Phalaris grass which drastically reduced the prevalence of Pink Eye in his herd.

The team at Evolve is customising their patented Bladerunner machines to suit farmers needs across Australia.

If you enjoyed this feature on regenerative agriculture, you might like our feature on hydrogen powered haircuts.